What is an Evaporator ?

Evaporator is one of the main parts of the cooling system. Evaporator absorbs heat from the area that needs cooling. As the refrigerant in the system occupies this area, it turns into a gas. The heat is transferred through the surface of the refrigerant tubes in the system which causes the temperature around the evaporator to drop.

Types of evaporator

1. Direct Expansion Evaporator

1.1 Finned-Tube Coil Evaporator

commonly used evaporator as fin coil, designed for the copper tube to be coiled and There are aluminum fins to increase the heat surface area to transfer heat to the liquid within the tube.

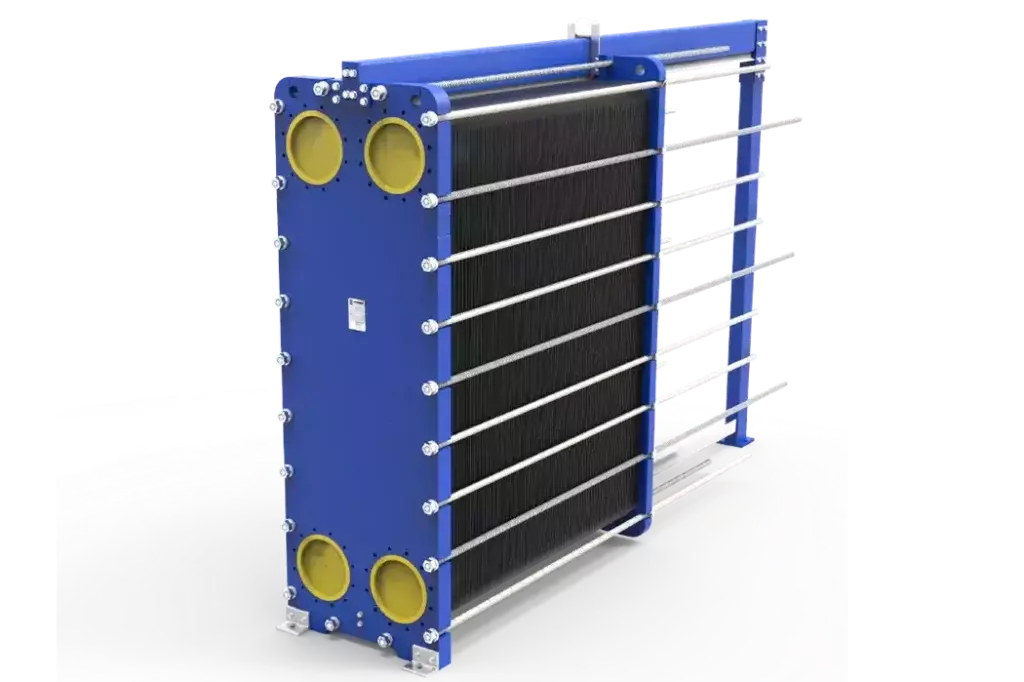

1.2 Plate Evaporator

that is very commonly used. This Evaporator does not have fins. And there are many different shapes.

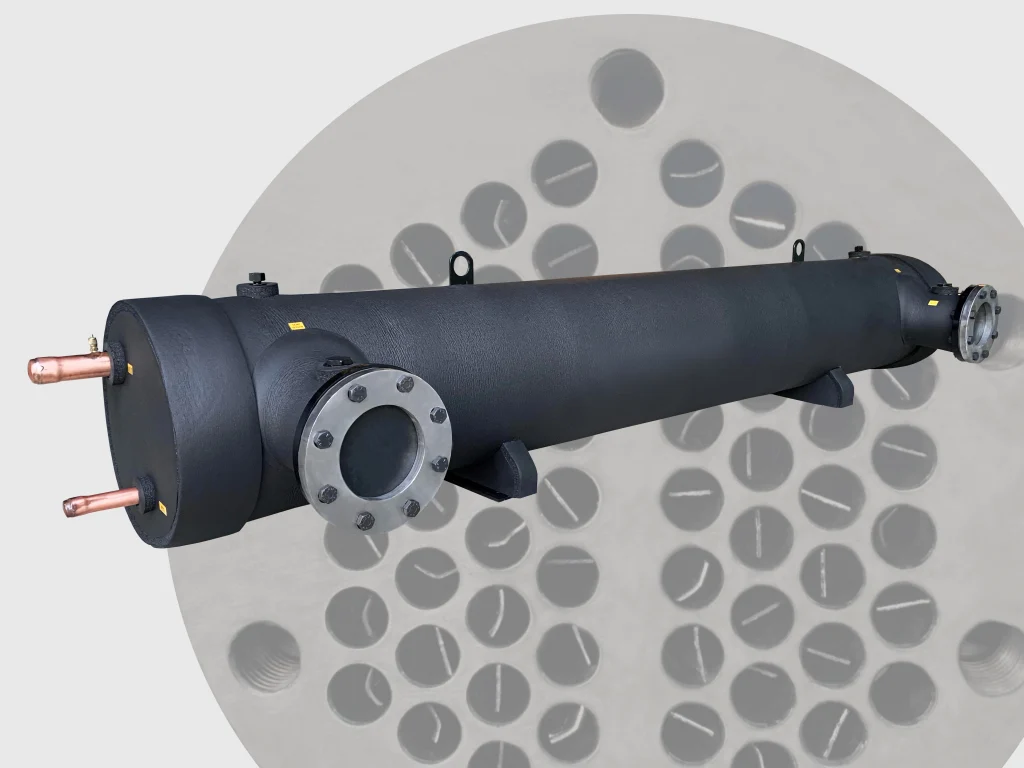

1.3 Shell and Tube Evaporator

consists of a pipe inside with a small tube arranged in a lot. Shell and tube evaporator is very commonly used with refrigeration systems, chillers , which are used to bring liquid refrigerant which is low temperature and low pressure. Inside this Evaporator absorbs the amount of heat from the water, turning it into cold water. and the pump circulates this cold water to cool the area or area that needs cooling one more time.

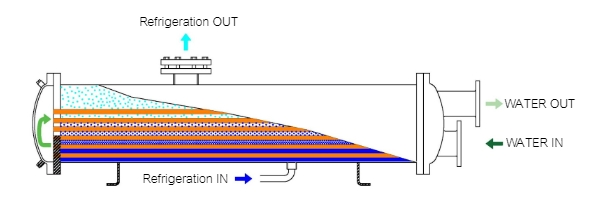

2. Flooded Evaporator

A Flooded Evaporator will look like a Shell and tube evaporator, but the difference is that the refrigerant is in the pipe (shell side) and the cold water runs inside the tube. The low pressure liquid refrigerant is constantly filled inside the evaporator. The liquid refrigerant is circulated through the coil by its own weight, and when the liquid refrigerant receives the amount of heat from the tube surface, It will change the state of the gas to float upward to send to the compressor next.

Shell and tube condenser design

2 PT. Co., Ltd. is an industrial manufacturer that produces heat exchangers, both in Shell and tube type, such as condensers, evaporators, and oil coolers that can be used for both tap water and seawater applications. In addition, we also produce air-cooled heat exchangers such Air condensing frames and fin coil products which can be used as condenser, evaporator and heat exchanger that exchanges between water and air.

The company can design and produce according to customer requirements such as

- Terms of space limitations for installation and maintenance on site : we can design products to have a shorter size.

- Terms of performance and capacity : The calculation program is used to obtain an accurate data sheet.

- Term of speed of design : There are engineers to consult and design and draft drawing immediately

- Terms of use and maintenance : for example, the company can design a heat exchanger in 4 circuits, which can switch the cover to 2 circuits on each side for ease of maintenance and piping on site.

from the above information We are therefore confident in our service and production. to meet the needs of customers in all aspects