Fin coils are one of the refrigerant systems. Fin coils are now used in a large number of refrigeration systems. Because it can be used in various functions such as evaporator coil, condenser coil and heat exchanger coil.

What is a Fin Coil ?

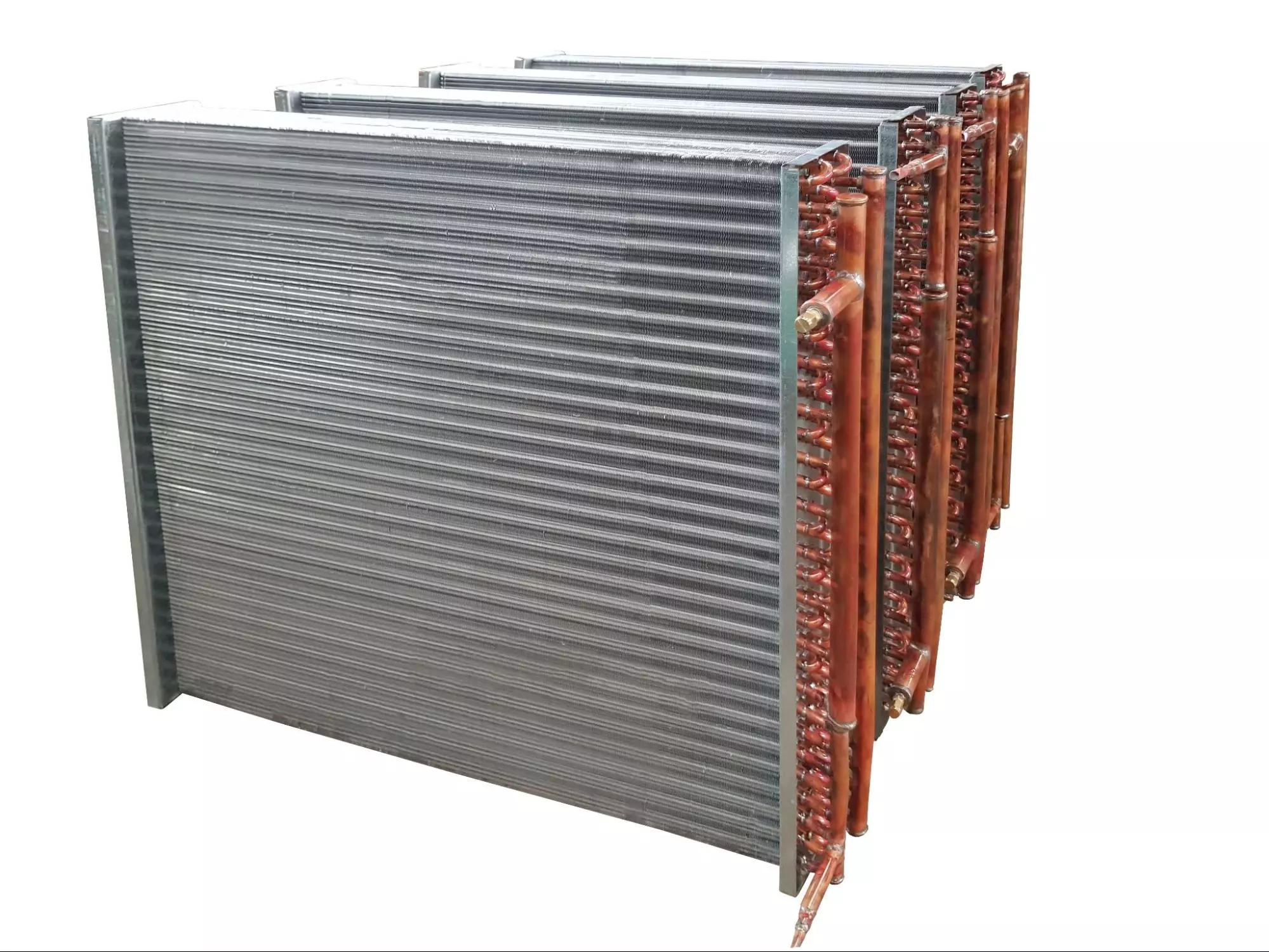

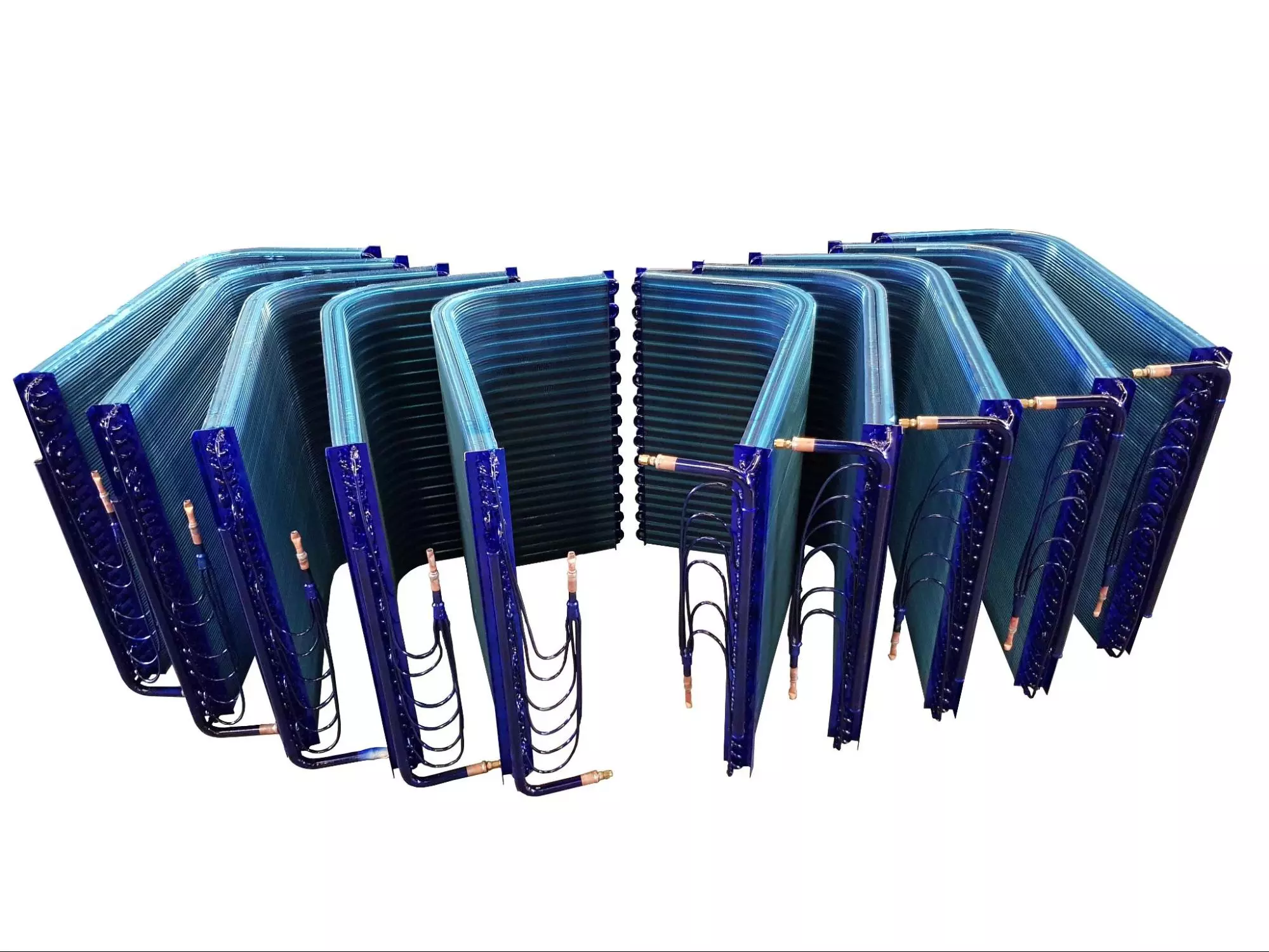

Fincore consists of 4 main parts: Aluminum fin, Tube, Header and Endplate which can act as

following ;

1. Condenser Fin Coil which is Air-cooled type The air acts to cool the refrigerant such as R22 R134A R404A R407C R410A, etc. so that the refrigerant in the gas state condenses into a liquid refrigerant.

2. Evaporative Fin Coil is one of the main components of the cooling system. The air is cooled by the heat exchange of a refrigerant such as R22, R134A, R404A, R407C, R410A, etc. This refrigerant is boiled, causing the transition from liquid to gas. As the air flows through the coil, the temperature is reduced. resulting in cold air flowing through.

3. Heat Exchanger Fin Coil is mainly a fin coil that exchanges air and fluids such as water and oil, etc. By working, it can work both to reduce and increase the air and fluid temperature depending on the purpose of use. The main components are composed of copper tube and aluminum fins. Most of the headers are steel. stainless steel and copper which is suitable for cold heat exchange systems

Fin coil inefficiency that caused by system change

The basics of finned tube coils and maximizing coil is capacity and efficiency.Fin coils are found in many process heating-cooling systems. In a dirty atmosphere, they can actually cause many systematic problems, including motor, pump, compressor and fan failures.

System changes that cause heating and cooling coil inefficiency :

- The fluid flow that is supplied to the system is higher or lower than the data calculated.

- The fluid temperatures that are supplied to the system are higher or lower than the data calculated.

- The air flow that is supplied to the system is higher or lower than the data calculated.

- The air temperatures that are supplied to the system are higher or lower than the data calculated.

- The fouling factor of fluid is higher than the data calculated.

- Air-side fouling. Coils are easily loaded with dirt, particles and bacteria because of their density. This increase in pressure reduces airflow and is a major contributor to decreases in system efficiency.

Fin coil cleaning

Fin coil maintenance is important. The used fin coil should be maintained by air blowing or spraying water to clean the coil every 3 – 6 months to prevent mucus from becoming dirty and dust stains attached to the fin oil. If dust or dirt is present, it will reduce the ability to exchange and transfer cold heat.

Characteristic symptoms of damaged fin coil are such as leaking coil at some points. This condition can be repaired by sealing the leak so that the core can continue to use. But if the fin coil leaks in many points until unable to repair, because reparing one point will spread to another point. symptoms like this should be replaced with a new fin coil. This is because rusted fincores will decrease its functionality and efficiency.

What is a fin coil comb?

The fin coil comb is used to smooth the curled and wavy aluminum fins of the aluminum fin. Using a fin-core comb directly carded on the aluminum fin by allowing the groove of the aluminum fin to match the groove of the comb. Fin coil comb can be used with fin coil ranging from small household appliances such as fin coil to outdoor condensing units to fincores and used in large industries.